Settings

Shipping country

Languages

- Products description

Products description

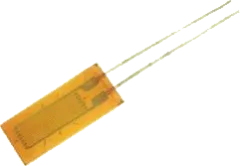

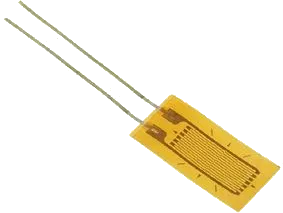

The film wire strain gauges are based on the effect of the dependence of the change in resistance on the deformation of the sensing element.

The linear nature (within a limited range of deformation) of this dependence allows the use of strain gauges to determine the deformations as well as the forces (strains) and moments acting on the elements under test.

Supporting film data:

- Material: modified epoxy-phenolic resin

- Thickness: 30 µm

- Insulation resistance: over 100 MOhm

- Dielectric strength: over 1 kV

Resistance network of strain gauges:

- Material: Constantan CuNi 44

- Temperature coefficient of resistance: 0.04 x 10-3/°C

- Thickness: 5 µm

Strain gauges:

- Thickness: 60 µm

- Operating temperature max.: 200°C

- Deformation max: 5%.

- Coefficient of deformation sensitivity "k"

(strain gauge constant): 2.15

- Tolerance of the coefficient of deformation sensitivity: 0.5%.

The resistance network of the strain gauge is located between two layers of a carrier foil, which has insulating properties.

The coefficient of deformation sensitivity "k" is a measure of the relative strain gauge resistance change with respect to the relative deformation.

The linear nature (within a limited range of deformation) of this dependence allows the use of strain gauges to determine the deformations as well as the forces (strains) and moments acting on the elements under test.

Supporting film data:

- Material: modified epoxy-phenolic resin

- Thickness: 30 µm

- Insulation resistance: over 100 MOhm

- Dielectric strength: over 1 kV

Resistance network of strain gauges:

- Material: Constantan CuNi 44

- Temperature coefficient of resistance: 0.04 x 10-3/°C

- Thickness: 5 µm

Strain gauges:

- Thickness: 60 µm

- Operating temperature max.: 200°C

- Deformation max: 5%.

- Coefficient of deformation sensitivity "k"

(strain gauge constant): 2.15

- Tolerance of the coefficient of deformation sensitivity: 0.5%.

The resistance network of the strain gauge is located between two layers of a carrier foil, which has insulating properties.

The coefficient of deformation sensitivity "k" is a measure of the relative strain gauge resistance change with respect to the relative deformation.

Last viewed: